Hot Forge

- Home

- Hot Forge

Tooling Capabilities

- Inserts

- Dies

- Punches and Pins

- Casing and Shells

- Bolsters

- Ejectors

- Trim Dies

- Machine Parts

Contact Us

1-708-489-0300

Get Quotation

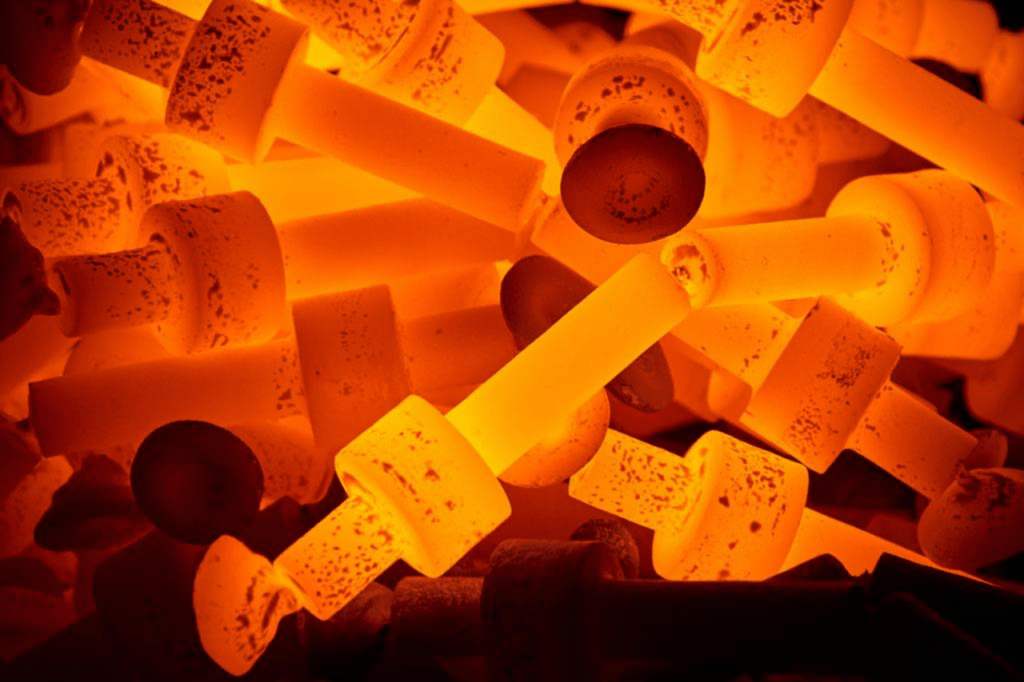

Hot Forging: Precision Shaping for Durable Components

Hot forging, also known as hot forming or drop forging, is a metalworking process that shapes metal at high temperatures. It’s used in many industries to create parts that are strong and durable, such as in the automotive, aerospace, and construction industries:

- Automotive: Hot forging is used to make parts like crankshafts, connecting rods, gears, and axles.

- Aerospace: Hot forging is used to make parts like turbine blades, landing gear, and structural parts.

- Oil and gas: Hot forging is used to make parts like valves, flanges, and fittings.

- Heavy machinery: Hot forging is used to make parts for hydraulic presses, mining equipment, and construction vehicles.

- Power generation: Hot forging is used to make parts like turbine shafts and generator rotors.

- Agriculture: Hot forging is used to make structural components for tractors, combines, and plows.

- Tools: Hot forging is used to make tools like drill bits.

Benefits of Hot Forging:

Hot forging results in components with enhanced strength, ductility, and refined grain structure. It is ideal for producing solid, robust metal parts from various materials, including aluminum, copper, steel, and advanced super-alloys.

Applications of Hot Forged Parts:

Hot forging is essential in manufacturing critical components across various systems, including:

- Engine Parts: Pistons, connecting rods, and crankshafts

- Driving Gears: Pinions and synchronizer rings

- Powertrain Components: Wheel hubs and universal joints

- Undercarriage Parts: Wheel carriers and axle journals

- Brake System Components: Brake plates and brake cylinders

Experience & Expertise: With years of experience in the tooling industry, we bring unparalleled expertise to every project. Our team understands the specific challenges faced in ammunition and firearms manufacturing and is dedicated to providing solutions that exceed industry standards.

No two projects are the same, which is why we offer fully customizable tooling solutions. Our engineers work closely with you to design and produce tools that meet your unique needs, ensuring optimal performance and longevity.

Ammunition Manufacturers: From small-scale operations to large, high-volume production facilities, our tooling solutions are trusted by ammunition manufacturers around the world.

Firearm Manufacturers: Precision tooling for the production of firearms, ensuring every component meets the highest standards of quality and safety.

Military and Defense Contractors: Providing specialized tooling solutions for the demanding requirements of military and defense applications.

Every tool we produce undergoes rigorous quality checks to ensure it meets the exacting demands of the ammunition and firearms industry. From material selection to final inspection, we are committed to delivering tools that perform flawlessly.

We stand by our products and provide ongoing support to ensure your operations run smoothly. From technical assistance to maintenance services, our team is here to help you succeed.

Contact Us

Ready to take your manufacturing capabilities to the next level? Contact J&J today to discuss your tooling needs. Our experts are ready to assist you with custom solutions that will help you achieve your production goals with precision and reliability.

Testimonials

What they say

The team at J & J Carbide & Tool consistently delivers exceptional quality and precision in their tooling. Their expertise and dedication to excellence have significantly improved our production process. Highly recommend!

Debbie J

We’ve worked with J & J Carbide & Tool for years, and their attention to detail and commitment to delivering on time is unmatched. Their tooling is top-notch, and their customer service is outstanding!

John M

Choosing J & J Carbide & Tool for our tooling needs was the best decision we made. Their craftsmanship and reliability have set a new standard for our operations. Truly industry leaders!

Rick SOwner

From cold header tooling to nut form tooling, J & J Carbide & Tool has been an invaluable partner. Their tools are durable, precise, and always meet our high standards.

Kirk GCEO

The quality and innovation from J & J Carbide & Tool have been game-changing for our business. Their expertise and commitment to perfection make them the best in the industry.

John BCEO